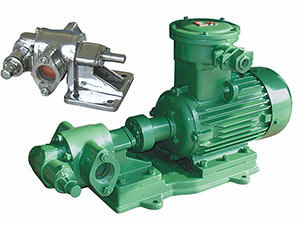

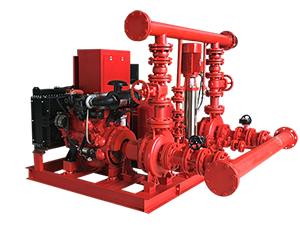

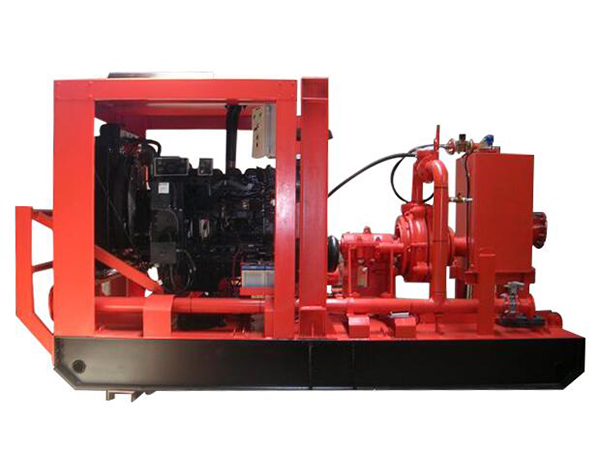

Defu Machinery is an enterprise involved in designing, developing, manufacturing and selling pumps, including self priming pump, end suction centrifugal pump, diaphragm pump, mixed flow pump, gear pump, diesel engine driven pump, fire pump and some others. Relying on the local industrial chain, DEFU has established its production base in Shanghai, Zhejiang and Jiangsu province. And we are the OEM manufacturer of Dongfeng Cummins engine.

-

- Quality ControlAn outstanding water pump comes from perfect mould. Through years of improvement, we adopt precision casting mould for water ... Read More

-

- Production CapacityDepending on the local industrial system, we have established 4 production bases in Shanghai, Hubei and Shandong province. Read More

-

- Sustainable DevelopmentAs an environmentalist, DEFU is prepared to take social responsibility, concerning about the company staff and the special groups in the society. Read More

Interested in our Products and Services?

Get in touch with us now.- Contact Us