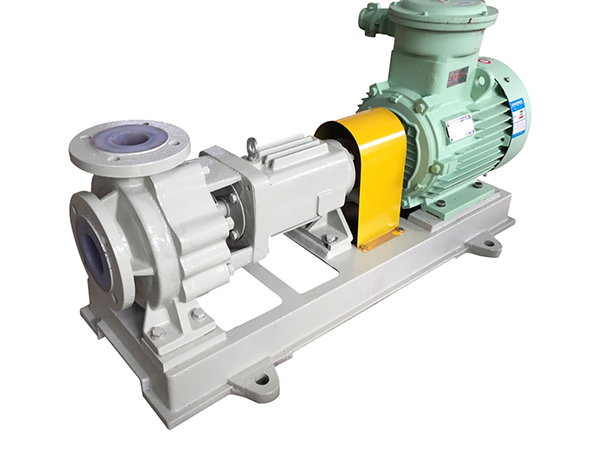

Centrifugal Chemical Pump

The centrifugal chemical pump is characterized by outstanding corrosion resistance and reliable sealing property. The single stage single suction pump features abrasion resistance, high temperature resistance, aging resistance, high mechanical strength, and nontoxicity.

The metal shell for the pump body is lined with FEP. The impeller, as well as the pump cover for the industrial pump, is entirely sintered and produced from metal inserts covered by FEP. The SIC/VITON mechanical seal is conducive to the outstanding performance of the centrifugal chemical pump.

- The corrosion resistant centrifugal pump can be used for delivering highly corrosive medium in any concentration, including vitriol, hydrochloric acid, hydrogen nitrate, acetic acid, hydrofluoric acid, aqua regia, alkali, strong oxidant, organic solvent, etc.

- This pump for corrosive liquid is also applicable for the technological process such as liquid handling, wastewater treatment, and acid supply in the industry like chemistry, pharmacy, petroleum, electric power, electroplate, pickling, pesticide, papermaking, and so on.

| Caliber Size | 32-100 mm |

| Rang of Flow | 2.5- 130m3/h |

| Head Range | ≤87m |

| Working Temperature | -85 ℃ to 200 ℃ |

| Type | Flow Rate | Head | Speed | Efficiency | Power | NPSH | Dia. of Pump | |

| m3/h | m | rpm | % | kW | M | Inlet (mm) | Outlet (mm) | |

| 6.3 | 20 | 2900 | 51 | 1.5 | 3 | 40 | 25 | |

| 6.3 | 32 | 2900 | 46 | 2.2 | 3 | 40 | 25 | |

| 6.3 | 50 | 2900 | 39 | 4-5.5 | 3 | 40 | 25 | |

| 6.3 | 80 | 2900 | 41 | 7.5-11 | 3 | 40 | 25 | |

| 12.5 | 20 | 2900 | 51 | 2.2 | 3 | 50 | 32 | |

| 6.3 | 5 | 1450 | 45 | 0.55 | 3 | 50 | 32 | |

| 12.5 | 32 | 2900 | 46 | 4 | 3 | 50 | 32 | |

| 6.3 | 8 | 1450 | 33 | 0.55 | 3 | 50 | 32 | |

| 12.5 | 50 | 2900 | 39 | 7.5 | 3 | 50 | 32 | |

| 6.3 | 12.5 | 1450 | 33 | 1.1 | 3 | 50 | 32 | |

| 25 | 20 | 2900 | 62 | 3 | 3.5 | 65 | 50 | |

| 12.5 | 5 | 1450 | 55 | 0.55 | 3.5 | 65 | 50 | |

| 25 | 32 | 2900 | 57 | 5.5 | 3.5 | 65 | 50 | |

| 12.5 | 8 | 1450 | 51 | 1.1 | 3.5 | 65 | 50 | |

| 25 | 50 | 2900 | 52 | 11 | 3.5 | 65 | 40 | |

| 12.5 | 12.5 | 1450 | 46 | 1.5 | 3.5 | 65 | 40 | |

| 25 | 80 | 2900 | 50 | 18.5 | 3.5 | 65 | 40 | |

| 12.5 | 20 | 1450 | 43 | 3 | 3.5 | 65 | 40 | |

| 50 | 20 | 2900 | 69 | 5.5 | 4 | 80 | 65 | |

| 25 | 5 | 1450 | 64 | 1.1 | 4 | 80 | 65 | |

| 50 | 32 | 2900 | 67 | 11 | 4 | 80 | 65 | |

| 25 | 8 | 1450 | 62 | 1.5 | 4 | 80 | 65 | |

| 50 | 50 | 2900 | 63 | 15 | 4 | 80 | 50 | |

| 25 | 12.5 | 1450 | 57 | 2.2 | 4 | 80 | 50 | |

| 50 | 80 | 2900 | 66 | 30 | 4 | 80 | 50 | |

| 25 | 20 | 1450 | 51 | 5.5 | 4 | 80 | 50 | |

| 100 | 20 | 2900 | 77 | 11 | 4.5 | 100 | 80 | |

| 50 | 5 | 1450 | 74 | 1.5 | 4.5 | 100 | 80 | |

| 100 | 32 | 2900 | 73 | 15 | 4.5 | 100 | 80 | |

| 50 | 8 | 1450 | 69 | 2.2 | 4.5 | 100 | 80 | |

| 100 | 50 | 2900 | 73 | 30 | 4.5 | 100 | 65 | |

| 50 | 12.5 | 1450 | 68 | 5.5 | 4.5 | 100 | 65 | |

| 160 | 32 | 2900 | 70 | 30 | 5 | 125 | 80 | |

| 80 | 8 | 1450 | 74 | 5.5 | 5 | 125 | 80 | |

| 200 | 50 | 2900 | 65 | 55 | 5 | 125 | 100 | |

| 100 | 12.5 | 1450 | 71 | 11 | 5 | 125 | 100 | |

| 200 | 80 | 2900 | 73 | 75 | 5 | 125 | 100 | |

| 100 | 25 | 1450 | 73 | 15 | 5 | 125 | 100 | |

| 200 | 32 | 1450 | 73 | 45 | 5 | 150 | 125 | |

| 200 | 50 | 1450 | 74 | 75 | 5.5 | 150 | 125 | |

| 400 | 32 | 1450 | 74 | 75 | 5.5 | 200 | 150 | |

| 400 | 50 | 1450 | 74 | 110 | 5.5 | 200 | 150 | |

Related Names

Chemical Pump | Centrigugal Pump

-

Get In Touch

-

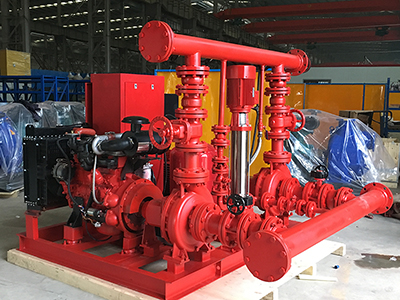

Defu Machinery was co-founded by Shanghai Y&L Pump Factory and Jiangsu SELE Pump Factory. We are committed to development, production, sell, and maintenance of various types of pumps, self priming sewage pump, air operated diaphragm pump, centrifugal pump, fire pump, diesel engine driven pump, irrigation pump, and some others.

More and more users choose our products, such as irrigation pump for Ministry of Agriculture Uganda, flood water pump for Government of Thailand, water drainage pump for open-pit coal mining in Indonesia and Guyana, ballast pump for SAIPEN company, underground drainage pump for using in Australia, and so on.